Defect analysis is a continuous process of quality improvement and planning. Detecting defects are classified into different categories and are also used to identify the possible causes in order to prevent the problems from occurring. It helps projects to identify how issues can be prevented and in reducing or eliminating significant numbers of defects from being injected into the system.

Compared with other industries, manufacturing is found to have 23 percent of unplanned downtime, where it is only 9 percent in other sectors. – ServiceMax Research

Close to 45% of manufacturers agree that they require a huge improvement in terms of human quality check done over assets. – GE Digital

Around 82% of companies irrespective of their sectors were found to have undergone unexpected production downtime at least once in the last three years. – GE Digital

Automating quality testing using machine learning can help manufacturers to detect 90% of production errors – Forbes Research

By 2023, automated defective analysis software will become mandatory for any industry and it will reaches a value of US$24.8 billion – BBC Research

A human-centric manufacturing analysis might always lead to error occurrence instead, an automated defective analysis system in India provided by Airpix carries out a detailed inspection over manufacturing and ensures perfect processing till the end. We deploy machine vision technology here to inspect the overall composure and assembly of the inner parts and also to sense their defective rate. Machine learning ensures zero defect occurrence and maintains the quality through inspection, where it assists the human resource to make proper alignment with the inner structure or rectify the damage occurred over the inner part.

By deploying our futuristic tailor-made automated software your tedious quality inspection and defect analysis process gets simplified, and now it becomes much easier to solve the production complexity.

Safety guidelines are mandatory procedures to be followed in any manufacturing plants without second thoughts, improper handling of materials might risk the life of a technician and also decimates the machines sometimes too, and it controls and monitors the entire manufacturing workplace for misplaced objects. Hence it is sensed to have control over machinaised human act pattern recognition in the plant. It is impractical to control this scenario under human supervision, and the machine visioned defective analysis tool created by us can be a proper remedy in avoiding this situation through fiery alarms. Our prefixed machine visioned tool will alarm the unauthorized access, and hence it indicates a fiery signal to the concerned supervisor regarding any hazardous happening. This high-end sensor streamlines the entire working pattern of employees in a plant to ensure the production result gets delivered in time.

Improper packaging might lead to damage or loss of materials, there is no 100% surety of safe, and compressed packaging with human interference. We provide the best alternative solution for this dispute using our enhanced defective maintenance tool in India that ensures all the end products are stiffly packed. The machine vision technology performs the cross-checking operation here where it ensures whether the end-product gets properly packed. If any of the SKU (Stock Keeping Unit) found to be unpacked then our software will automatically indicate the concerned departmental staff to carry out the packaging process using machine learning techniques.

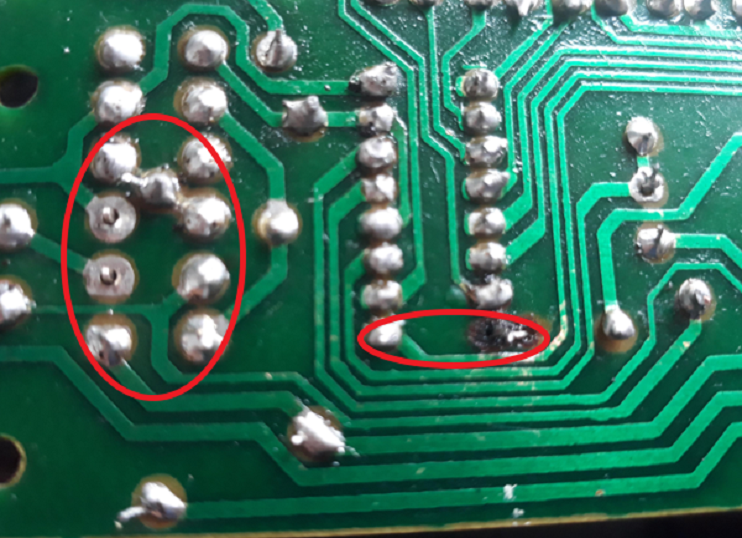

We deploy machine vision technology here to inspect the overall composure and assembly of the inner parts. Machine learning ensures zero defect occurrence and maintains the quality through inspection, where it assists the human resource to make proper alignment with the inner structure or rectify the damage occurred over the inner part.

Measuring product gauge in the manufacturing clan is a highly tedious process that requires an exclusive quality assurance team. Our proficient component assembly defect analysis tools using AI for manufacturing industries carries out a self-driven process of product verification by ensuring the exact dimensions are properly incorporated.

Paints are an integral part of the manufacturing system. We carry out a detailed defect analysis using AI for manufacturing industries that gives special focus over paint surface defects to ensure complete quality. Starting from sensing contamination defect to weld accuracy our automated tool carries out end-to-end inspection.

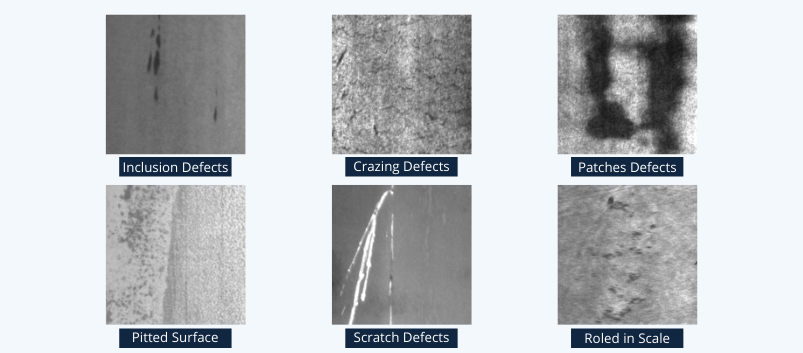

We have created a proficient defect analysis tool using machine vision that implements a detailed quality control mechanism to detect and sort out unknown setbacks over the steel surface. Right from sensing the missing part and evaluating dimensional accuracy. Our tool carries out a 360-degree quality control approach.

Our AI based defective analysis tool for the manufacturing industry ensures proper assembly of components to bring out the required product in time and deliver it to the customers. By carrying out a structured quality control check, our automated tool makes sure that best in the class of particles assembled to bring out the desired end product.