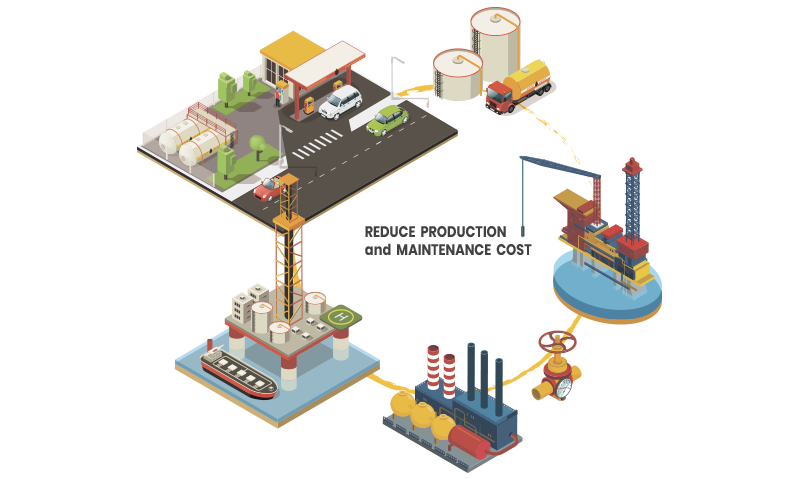

The Oil and Gas Industry faces many challenges in its operational processes, ranging from unconnected environments to frequent downtime and maintenance issues for its various machines. In comparison to other sectors, oil and gas has made fewer investments in incorporating artificial intelligence and machine learning technologies in its processes.

However, oil and gas companies have started on the path of AIML after witnessing how the technology has helped cut operational costs and enhance efficiencies across other industries.

One of the challenges in the oil and gas industry is identifying improper threading in pipelines or defects in error-prone mechanisms. Defects found at the end of the production line from upstream issues cost factory and budget resources. For example, if the defected oil pipeline or machine is installed into production, this could result in severe damages. These losses are comparatively far higher than the cost of AIML adoption.

Deploying a computer-vision based system can verify the quality of production and provide deep insights of defects in analytics. AIML powered Defect Detection solutions are cost-effective and are extremely economical in comparison to the prevailing processes.

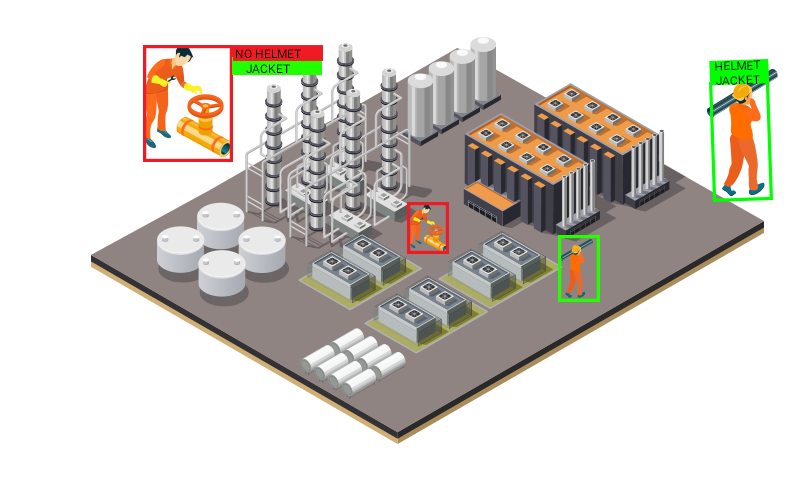

Oil and gas plants operate in extremely critical environments and the risk of injury is much higher than traditional manufacturing environments. Employees in oil plants work under different temperatures, are sometimes exposed to toxic fumes and must be aware of many moving mechanisms. Not following proper safety protocols can result in injury and financial penalties.

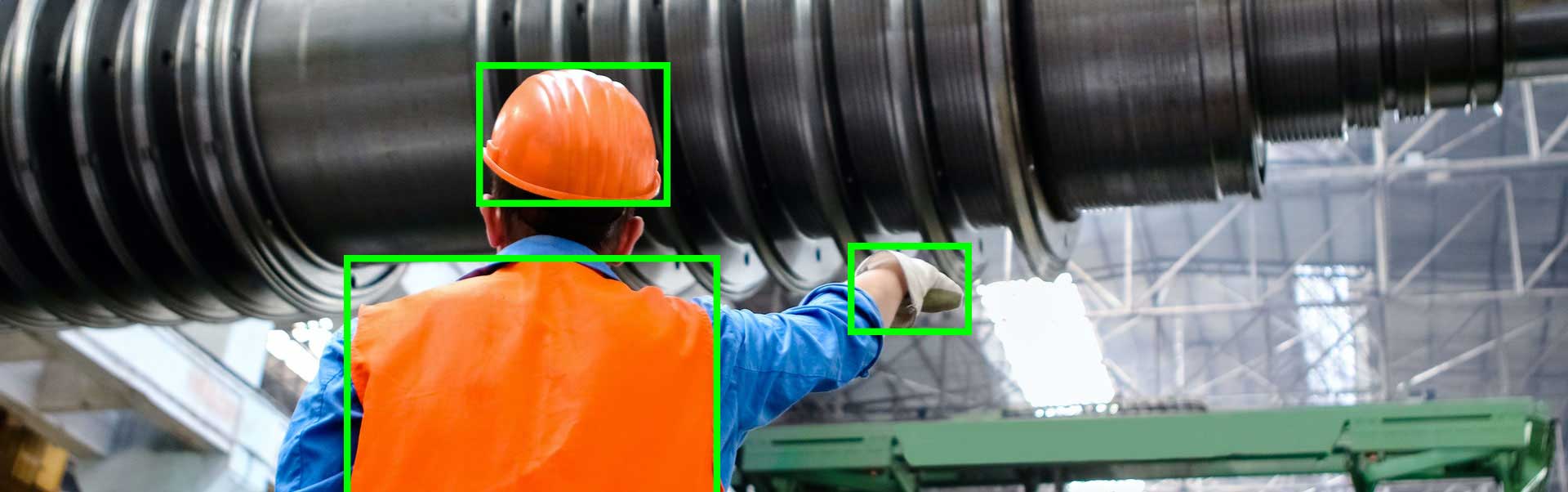

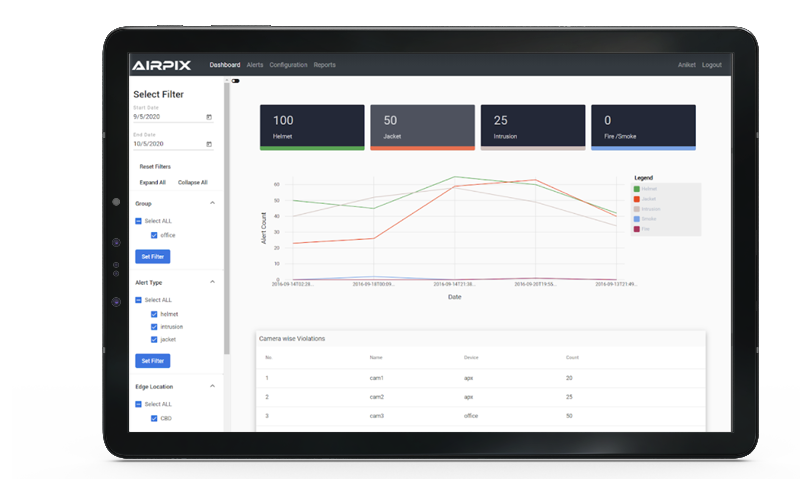

Companies are obliged to adhere to safety standards enforced by law. Not adhering to these standards result in hefty fines. Even though there is a ton of data to monitor safety issues, it is still a largely manual processes, such as manually monitoring camera feeds or physical safety sweeps, to make sure measures are effective. Current solutions only ensure employees are wearing Personal Protection Equipment (PPE) at the point of entry into the plant, not throughout the workday.

An AI-powered computer-vision solution can monitor the work site to ensure workers are following safety procedures without any deviations. The camera data is fed into an AI algorithm which will then be analyzed to send alerts and proactive recommendations. AI solutions can alert management even for the smallest deviations in compliance.

Oil or gas extracted using oil rigs is stored in a central repository and then distributed across pipelines. Due to various temperatures and environmental conditions, oil and gas components often face material degradation and corrosion. Corrosion can cause component deformation, which results in faded threading or can weaken the pipeline itself. Not handling this problem can result in catastrophic damages halting the entire production process. This is one of the biggest concerns of the industry and companies employ corrosion engineers to monitor and handle the health of components to avoid corrosion activities.

AI solutions can prevent incidents like this from occurring. AI and IoT technologies can detect signs of corrosion by analyzing various parameters using knowledge graphs and predictive intelligence to approximate the corrosion occurrence probability and raise alerts to pipeline operators. This way companies can be proactive in handling the corrosion risks and moreover, based on knowledge graph analysis, study various machinery downtimes and predict time to carry out maintenance activity. This way, companies plan and adjust for downtime.

Oil and gas businesses deal with lots of data coming from manufacturing processes but due to a lack of proper analytics tools, they’re unable to capitalize on the massive data resting in data silos. Companies can employ data engineers to manually analyze data to draw insights, but this is a limited option in time and cost furthermore, no amount of data engineers can possibly get to all the data that’s produced in a single day of operations.

Big Data powered AI applications derive intelligence and meaning out of the plethora of operational data. Artificial intelligence can be used to gather information into segments and uncover patterns or inconsistencies to make predictions out of the large data sets.

AIML algorithms study various data streams from various sensors and machinery of different plants or entire Geoscience data and extract real-time analytics to generate intelligent suggestions based on business needs. These deep insights enable geoscientists to have better visibility of the overall processes and operations, thereby enabling them to make better strategic decisions. This leads to improved operations efficiency, cost reduction and even reduces the risk of failure.

Exploring new insights in OIl and gas industries can be eased by using AIML to make this process easier and gather precise data, adopting autonomous AI-powered robots for exploration is a great solution. Top oil and gas companies are using drones to gather seismic images while image processing algorithms extract information. Based on these analyses, explorations are carried out. This process minimizes human risk and ensures accurate data.