Since the rise of the internet, the world’s top-producing factories have digitized their operations. Now, terabytes of data flow from almost every tool on the factory floor, giving organizations more information than they know what to do with.

Unfortunately, many companies lack the resources to translate this information to reduce costs and increase efficiency. For that, companies need Artificial Intelligence.

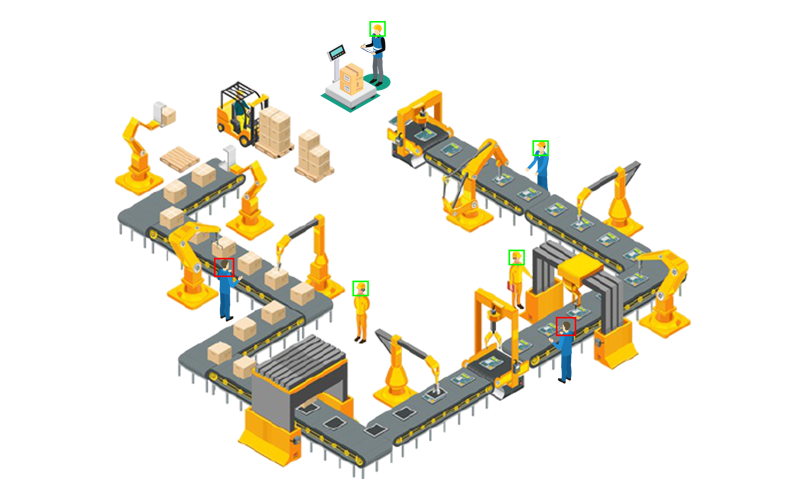

Today, many assembly lines have no systems or technologies in place to identify defects across the production line. Even those which may be in place are very basic, requiring skilled engineers to build and hard-code algorithms to differentiate between functional and defective components. The majority of these systems cannot still learn or integrate new information, resulting in countless false-positives, which then have to be manually checked by an on-site employee.

By imbuing this system with artificial intelligence and self-learning capabilities manufacturers can save countless hours by drastically reducing false-positives and the hours required for quality control.

Manufacturing requires acute attention to detail, a necessity that’s only exacerbated in the electronics space. Historically speaking, quality assurance has been a manual job, requiring a highly skilled engineer to ensure that electronics and microprocessors were being manufactured correctly and that all of its circuits were properly configured.

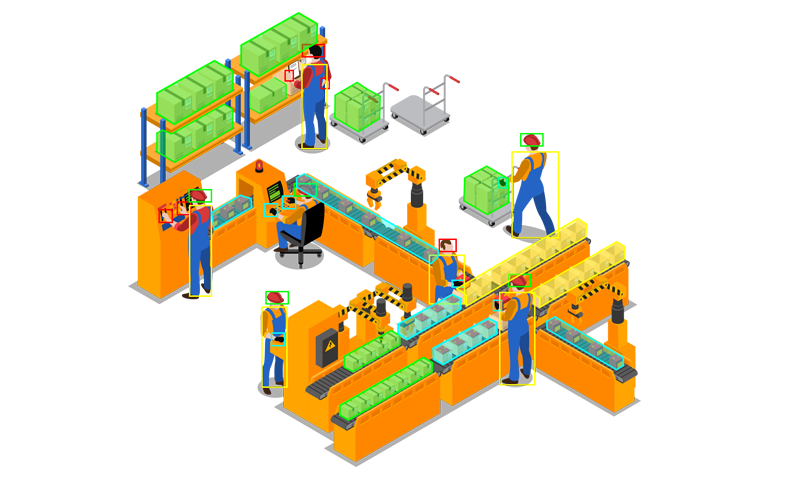

Today, image processing algorithms can automatically validate whether an item has been perfectly produced. By installing cameras at key points along the factory floor, this sorting can happen automatically and in real-time.

Edge analytics provides fast and decentralized insights from data sets collected from sensors on machines. Manufacturers collect and analyze data on the edge to reduce time to insight. Edge analytics has three use cases in manufacturing:

Artificial intelligence app in manufacturing allows you to manage order records and delete/add new inventories. Here, we should talk about machine learning technology. It was one of the most significant technologies that is used for managing supply, demand, and inventories.

By layering Artificial Intelligence into an IoT ecosystem, this wealth of data, you can create a variety of automations. For example, when equipment operators are showing signs of fatigue, supervisors get notifications. When a piece of equipment breaks down, the system can automatically trigger contingency plans or other reorganization activities.